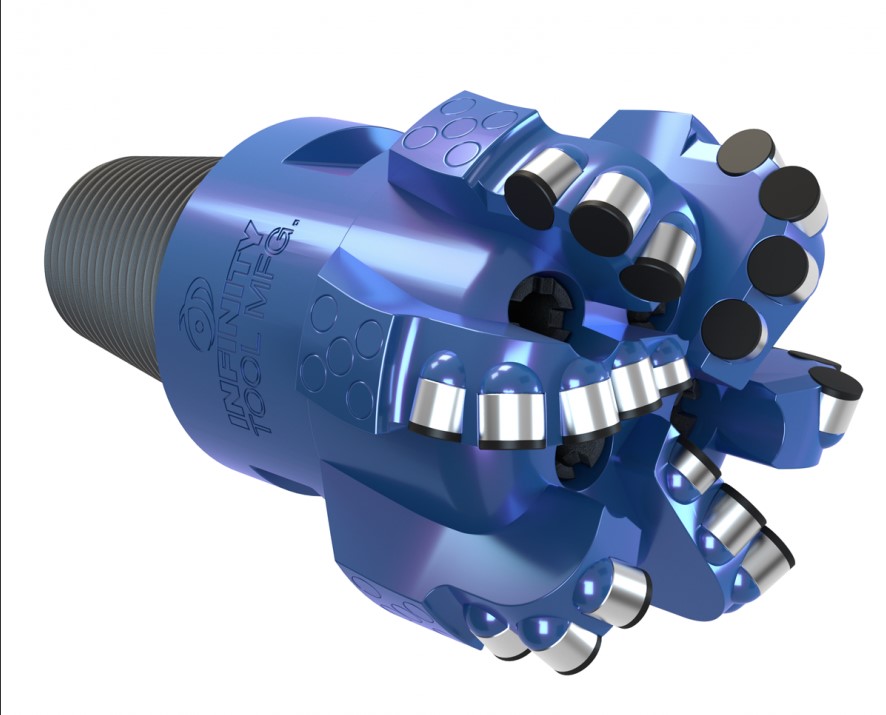

PDC Bit

We Supply PDC Drill Bits ranging from 3 1/2″~26″ suitable for a range of drilling applications including Horizontal Directional Drilling, Water well Drilling, Oil & Gas, Geo-Thermal, Construction as well as Mining.

Features

PDC cutter technology made a perfect performance on impact strength resistance and abrasive resistance.

Enhanced bit stability for BHA shock and vibration mitigation.

Increase cleaning and reduce balling.

Arc-surface PDC protection made the gauge more abrasion resistance and more radial vibration resistance than the TSP protection.

The FEA software for the cutters distribution and layout made the drilling more efficient and reduce NPT.

Optimize the angle of the cutter in both axial and radial by FBS(force balance analyze) software resulting in stronger aggressive and more durability of the bit.

DOC(depth of cutters) was calculated and optimized by a series experiences of the bit,made the cutter penetrate the formations more rationally.

Effectively improve the stability and ROP of the bit by spiral blade.

Gauge length

Short: Improved bit steerability and tool face control for directional or horizontal drilling, reduce slide section by achieve builds more quickly.

Extend: Enhances bit stability and allows more area for gauge protection components, improves bole hole quality.

Active gauge

Protect the gauge and improved hole quality.

PDC Cutters

Different features of PDC cutters can be chosen in different wells or formations for both drill efficiency and economic.

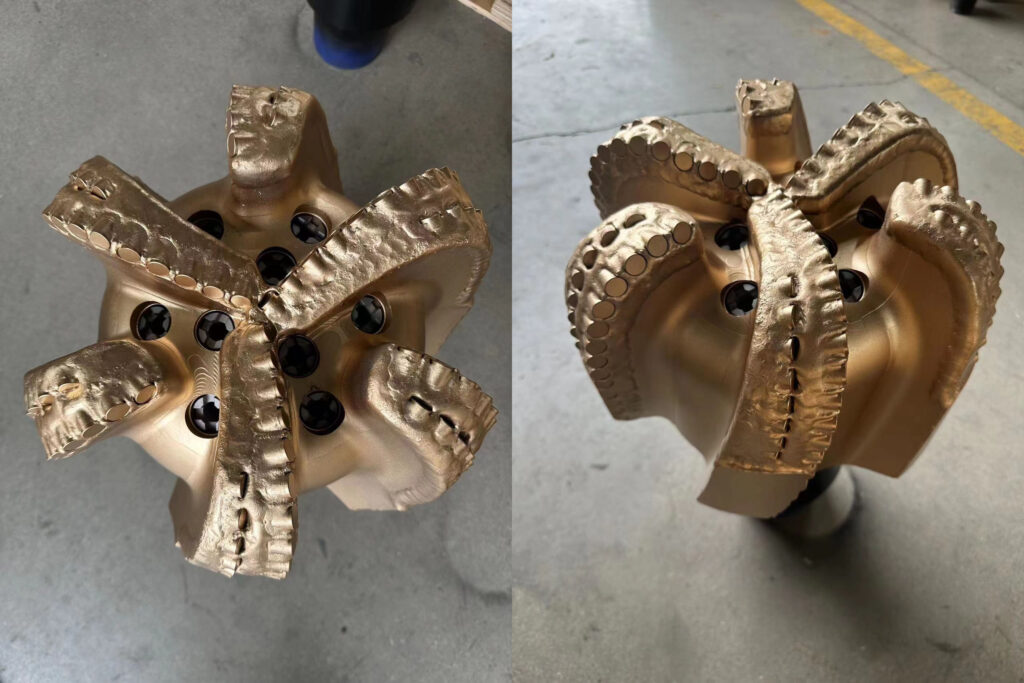

| BIT SPECIFICATION | |

|---|---|

| Bit Type | 12-1/4" GS1606T |

| IADC Code | S423 |

| Blade | 6 |

| Cutter Size (mm) | Φ 16MM; Φ 13MM |

| Cutter Qty | Φ16X49; Φ 13X56 |

| Nozzle Qty/Type | 6NZ |

| Gauge Length (mm) | 88 |

| Connection | 6-5/8" API REG |

| N.W./G.W.(KG) | 112/137 |

| Nozzle Size (inch) | 16/32; 18/32 |